| Band heaters | |

|

|

Product overview |

|

|

Enquire for a quotation or place an order. |

|

|

Standard |

|

|

Stock |

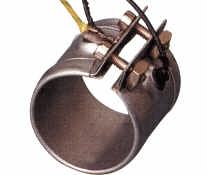

Band heaters |

|

|

|

![]()

|

Band heaters are designed to heat up cylindrical parts by conduction. The are used in many manufacturing processes such as the injection, extrusion and moulding processes … or other specific applications such as tank heating and they are to be found in many industries such as the plastic processing industry, the car industry, chemical and food processing industries, etc… Made with mica or ceramic insulators, bare tubular elements or cast aluminium, they can be water tight or fitted with a thermal insulator. |

Choosing between various technologies will depend on operating conditions such as temperature, power and environment.

Choosing between various types of connections will depend on installation and operating requirements.

Below examples show how numerous the possibilities and this is only a glimpse of the many types and options that are available. An online technical guide allows you to specify your needs and requirements. Furthermore, a wide range of standard products is available ex-stock.

Mica Band Heaters

Designed for use upto 450°C (842°F), i.e. a maximum specific Watt density of 6W/cm2 (40W/sq inch)

They consist of a nickel chromium resistance wire (80% nickel, 20% chromium) wound onto a mica sheet and protected by a metal sheath made of brass, steel or stainless steel.

Technical specifications, connections, various types and options are described in technical assessment for a price enquiry or a purchase order.

| Lead wire band heaters See ex-stock product list |

Embossed band heaters See ex-stock product list |

Sealed nozzle heaters See ex-stock product list |

|

|

|

| Pin plug connector band heater | Wire connector band heater | Band heater with temperature sensor receiver |

|

|

|

Ceramic band heaters

|

For use up to 900°C (1652°F), they operate by

conduction and radiation.

Extra features can be added in order to reduce surface temperature, avoid all risks of burns and reduce energy consumption. Technical specifications, types of

connections, various models and options are described in

Technical assessment for a price enquiry or a purchase order. |

Tubular element band heater

|

A stainless steel tubular element is coiled into a cylindrical shape and inserted into a metal ring clamp. Designed to withstand difficult conditions such as vibrations and corrosion, they are manufactured according to your requirements. |

Aluminium or bronze cast band heaters

|

One or more tubular heaters are coiled into a cylindrical

or half-cylinder shape and cast into bronze or aluminium.

Those heaters are designed for applications in difficult environments and applications requiring very good reliability and good heat distribution. For every new product a technical study has to be carried out. |

Advice :

Make sure that part that needs heating up is perfectly clean before fitting band heater in order to avoid all risks of material intrusion underneath heater and risks of smoke and fire.

After first use, tighten band heater again to ensure good surface contact and heat transfer in order to improve heater life span.